City of Gillette, Wyoming

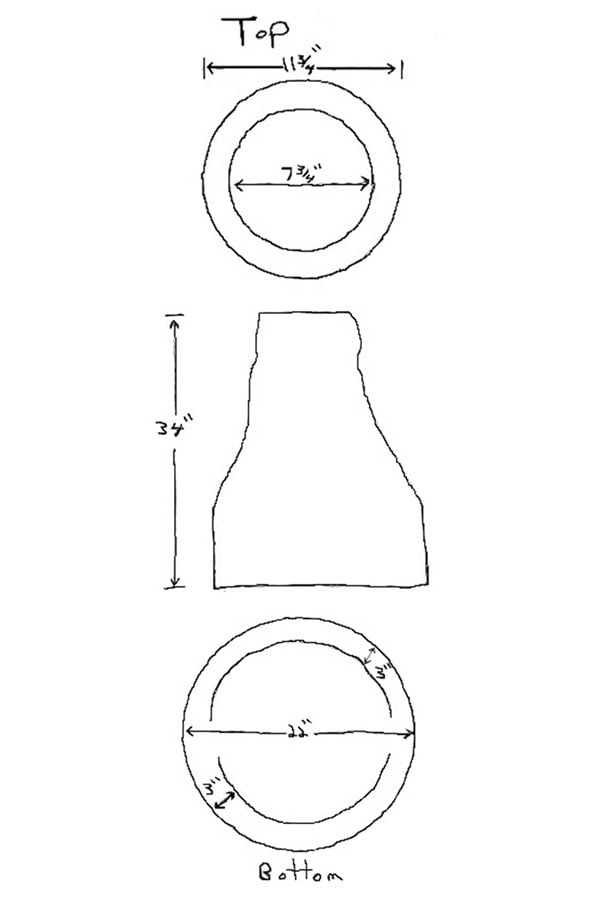

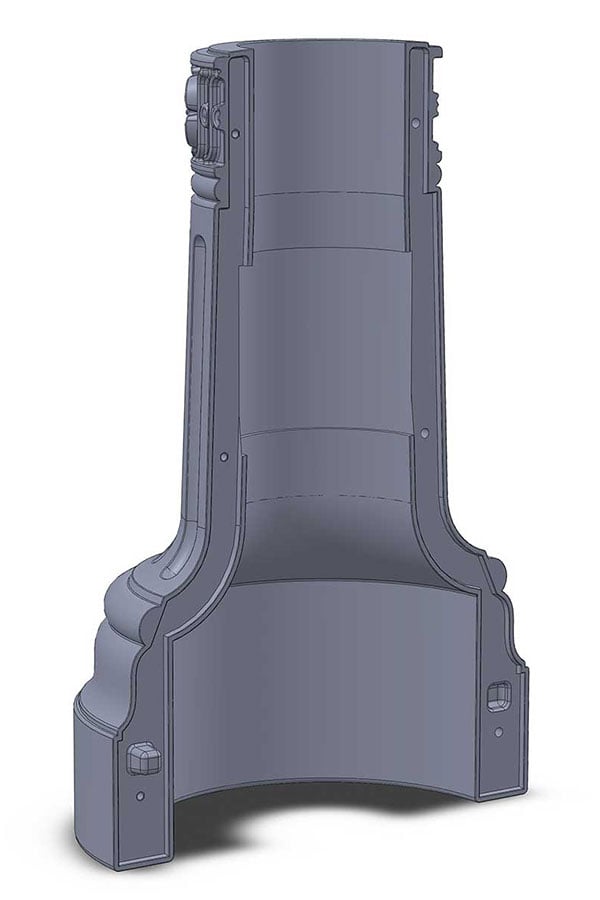

Custom Light Pole Base Covers – Gillette Base

Project Year: 2015

Project Overview

The City of Gillette, Wyoming, faced ongoing maintenance challenges with its decorative aluminum light pole base covers. Due to the city’s extreme winter conditions—where temperatures drop below zero for more than half the year—along with heavy road salt usage, the aluminum bases corroded quickly, requiring frequent replacements and costly upkeep.

To address this issue, TerraCast® Products provided a long-term, maintenance-free solution by replicating the city’s existing base cover design using LLDPE resin. This innovative material is impervious to rust, resistant to harsh weather conditions, and requires no ongoing maintenance.

The Challenges:

- Extreme Cold: Temperatures frequently drop below zero degrees Fahrenheit for over half the year.

- Road Salt Exposure: Heavy salt application for ice control led to rapid corrosion of aluminum base covers.

- High Maintenance Costs: The city had to regularly replace and maintain their aluminum base covers due to rust and damage.

The Solution:

By adhering to the original design specifications while using a superior material, TerraCast provided a solution that was both functional and aligned with Gillette’s vision. The transition to LLDPE resin marked a significant turning point in the city’s efforts to combat environmental wear.

TerraCast® Products replicated the design of the existing aluminum base covers using LLDPE resin, which offers several key benefits:

- Corrosion Resistance: Unlike aluminum, LLDPE does not rust or deteriorate from salt exposure.

- Maintenance-Free: The city eliminated costly repairs and replacements.

- UV Protection: Color-thru material prevents fading, ensuring long-term aesthetic appeal.

- Impact & Chip Resistance: Unlike metal or fiberglass, the material resists cracks, dents, and chipping.

The Result: 10 Years Later

Key Takeaways

- Material matters: LLDPE resin offers superior durability over traditional aluminum.

- Cost savings: Eliminating corrosion-related maintenance leads to significant long-term savings.

- Sustainability: Longer-lasting materials reduce waste and resource consumption.

About Us

All of our products are made in America. All offices, warehouses, facilities and factories stand proud on US soil. Originally founded in 1969, we have remained an American owned and operated company.

Our Products

A Terracast® product is designed to beat out the competition in every conceivable way. Our products are customizable, lightweight, weather/graffiti resistant, eco-friendly, and almost indestructible.

Contact Us

When you contact Terracast® you will always be met with a friendly voice. We want to make sure you are well taken care of whether you're a new customer or have been doing business with us for 20 years.